Welcome to the Decoupling System Simulator for Flaked Products

Loading sign-in options...

About the Model

The Decoupling System Simulator for Flaked Products is a webapp simulator built by the creators of ReliaSim.

This model uses a one-year history of measured production flow from the vitamin weigh belt, providing a real operational baseline for comparing simulated and actual system performance.

Manufacturers can use the simulator to:

- Explore alternative process flows and storage strategies

- Quantify the effect of off-ramp and on-ramp systems on utilization

- Measure downtime, surge capacity, off-ramp (to tote storage thru corn grit stabilization) and on-ramp (corn grit reconstitution) strategies

- Validate improvement ideas with predictive accuracy before implementation

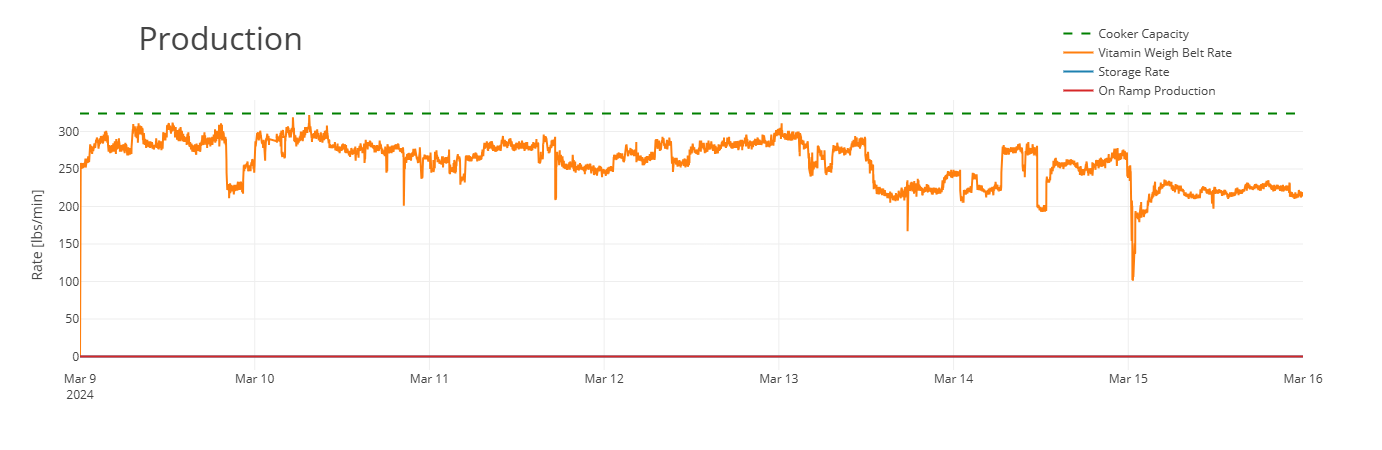

The Production Challenge

In a typical cereal line:

- Cookers run in parallel, producing conditioned corn.

- Ovens finish the product before packaging.

- Data shows cooker capacity often exceeds oven throughput — leaving unused potential.

The simulator visualizes:

- Green Line: Upstream cooker capacity

- Orange Line: Downstream oven output

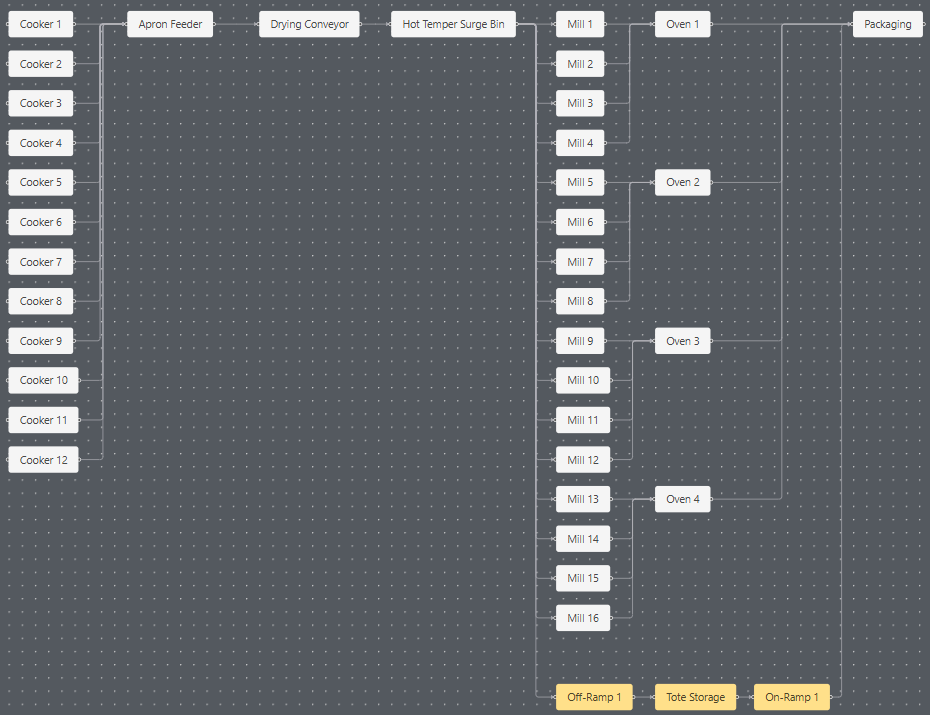

System Configuration

Production Flow

• 12 Parallel Cookers — hydrate and cook corn.

• Apron Feeder & Drying Conveyor — transfer and reduce moisture.

• Hot Temper Surge Bin — balances flow and provides buffering.

• 16 Mills → 4 Ovens — grind, toast, and finish product.

• Packaging — final stage of the process.

Decoupling Modules

The objective is to maximize cooker production by adding the decoupling capability yielding smarter flow control.

Off-Ramp: Removes excess flow when surge capacity is high, through a Dryer that stabilizes corn grit (~10–11% moisture).

Tote Storage: Stabilized corn grit is stored in totes. This effectively decouples the system.

On-Ramp: Feeds stored grit back into the line when packaging capacity is available.

How the Simulator Works

ReliaSim's Discrete Rate Simulation engine models the entire production flow using rate-based dynamics rather than individual units — the same physics that operators think in terms of: flow, downtime, and throughput.

This DRS-powered simulator:

- Runs annual production scenarios in seconds, not hours.

- Enables real-time scenario testing during meetings or coaching sessions.

- Uses decision-first modeling — start with the operational question, not a data-cleaning project.

User-controlled parameters:

- Number of off-ramp and on-ramp machines

- Tote Storage Capacity

- Ramp transfer rates and activation triggers

- Hot Temper Surge Bin capacity

- Planned downtimes and recovery rules

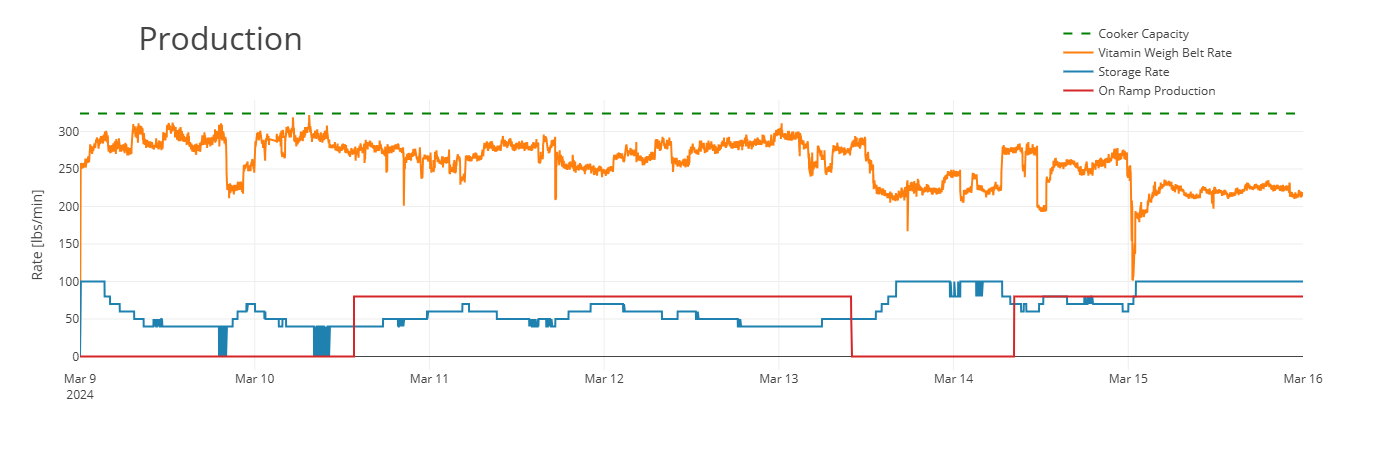

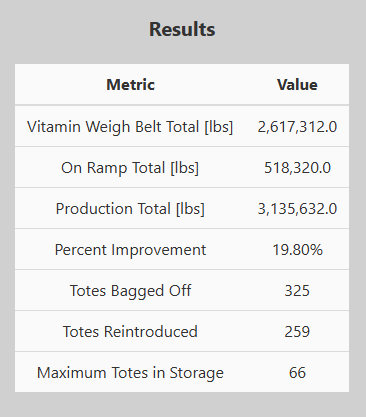

Outputs include:

- Profile of active Cookers

- Production curves: Cooker vs. oven throughput

- Packaging Load

- Hot Tempered Surge Bin Level and Tote Storage Inventory

- Efficiency and utilization metrics validated against actual data

Why ReliaSim + DRS Matter

Traditional simulation tools require specialists and take months to calibrate. ReliaSim compresses that into minutes, empowering engineers and plant managers to answer strategic questions during a meeting.

ReliaSim Advantages

- 1% efficiency accuracy validated against real production

- 1,200× faster than legacy discrete event tools

- Plant-manager accessible — no simulation expertise required

- Decision-first methodology that reveals hidden bottlenecks and counterintuitive improvements

DRS Foundation

- Models flow, not individual parts — perfect for cereal, chemical, and food operations

- Originally developed for modeling a multi-stage breakfast cereal plant, now rebuilt with modern data and speed

- Converts "What happened?" data into "What will happen if…?" predictive insight

Together, they transform simulation from a planning exercise into an operational decision tool for continuous improvement.

Key Insights

The Hot Temper Surge Bin acts as a dynamic buffer; right-sizing prevents cooker idle time.

The Off-Ramp Dryer preserves oversupply rather than wasting it.

The On-Ramp module converts stored product into extra throughput when capacity opens.

Proper configuration can increase effective production by 20% or more during key demand periods.

See the Simulator in Action

1-minute overview of how the simulator works

Checking access...